Servo Controlled Programmable Light Switch

Summary:

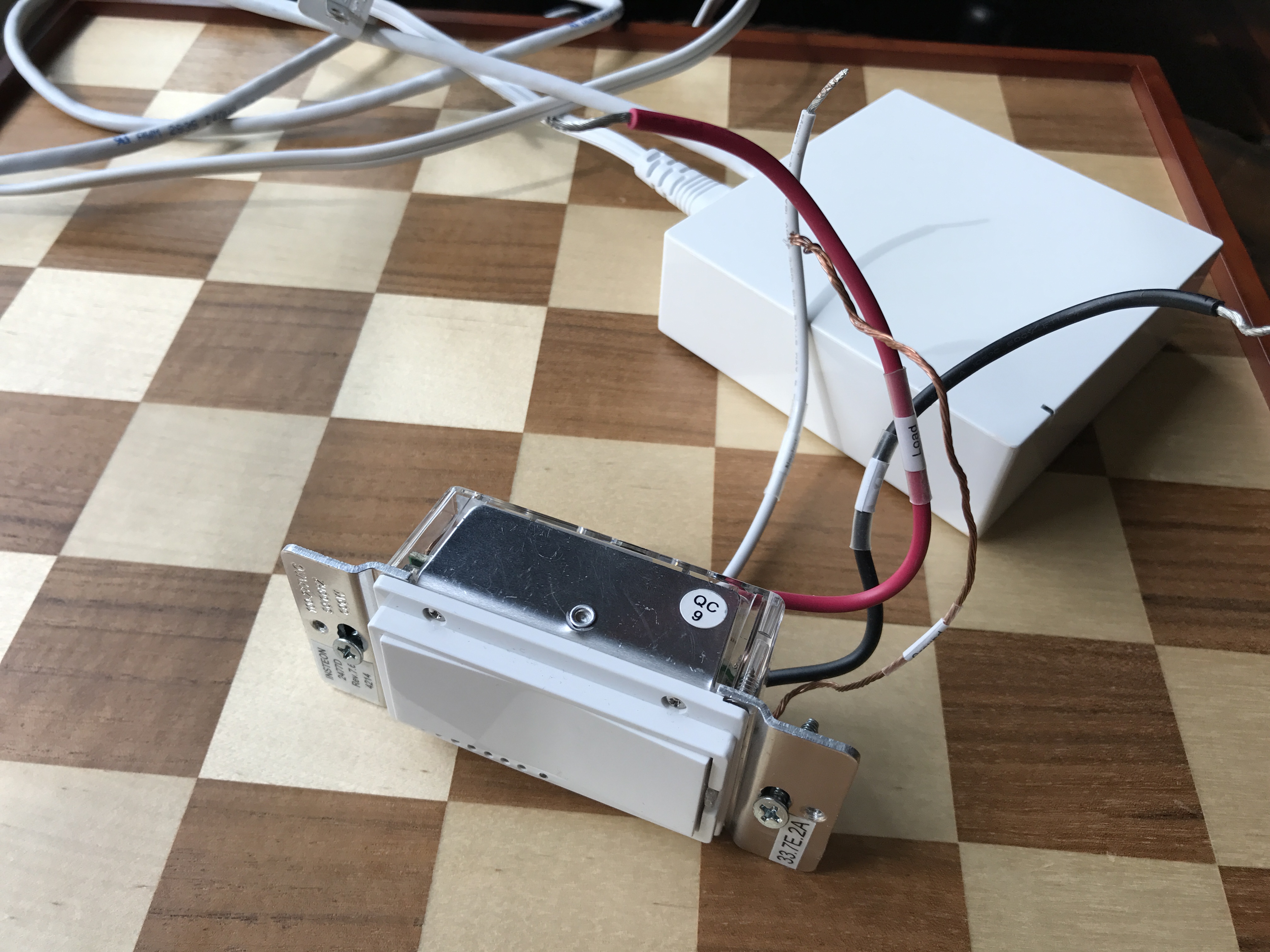

I began noticing problems with the low demand for automated light switches. After doing some research, I came to the conclusion that the two biggest deterrents that turn off the everyday consumer are high pricing and difficult installation. I took these two problems and combined them to create a solution that addresses both concerns. I have created a product anybody can install along while maintaining a low price point . As you can see from the pictures below, I wanted to understand the reason why most of these products had such a high cost. I was able to engineer an automated light switch that will cut down the price and and increase ease of use by utilizing a mobile device.

Execution:

I saw that a lot of automated light switch products were using zigbee which did have a higher cost because they run through a higher frequency at 2.4 GHz. Most of these devices run through this network. So you could even potentially shut them off when you are away from the house. However, this would only be possible through their central hubs which would be an additional purchase.

Execution:

I saw that a lot of automated light switch products were using zigbee which did have a higher cost because they run through a higher frequency at 2.4 GHz. Most of these devices run through this network. So you could even potentially shut them off when you are away from the house. However, this would only be possible through their central hubs which would be an additional purchase.

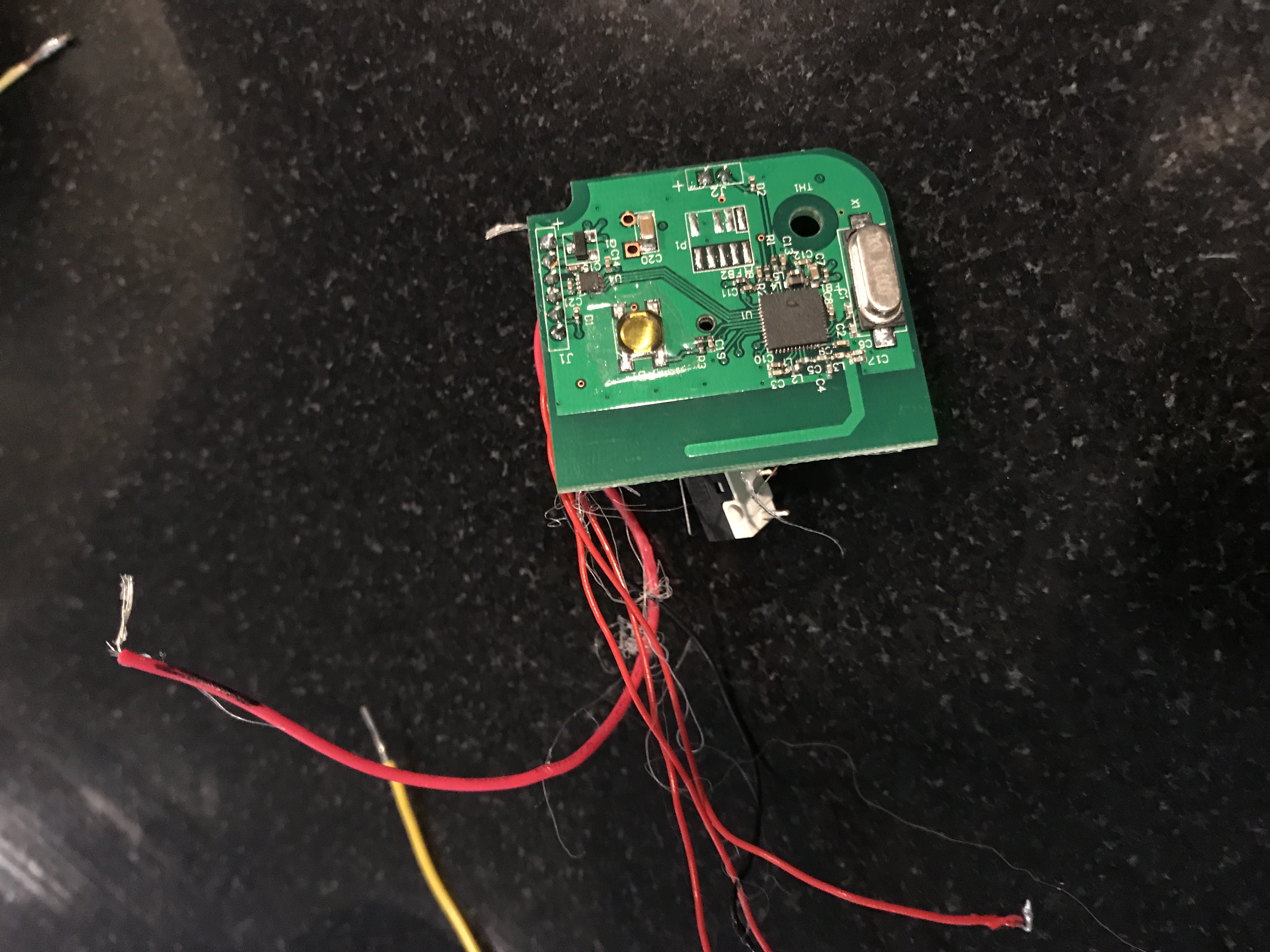

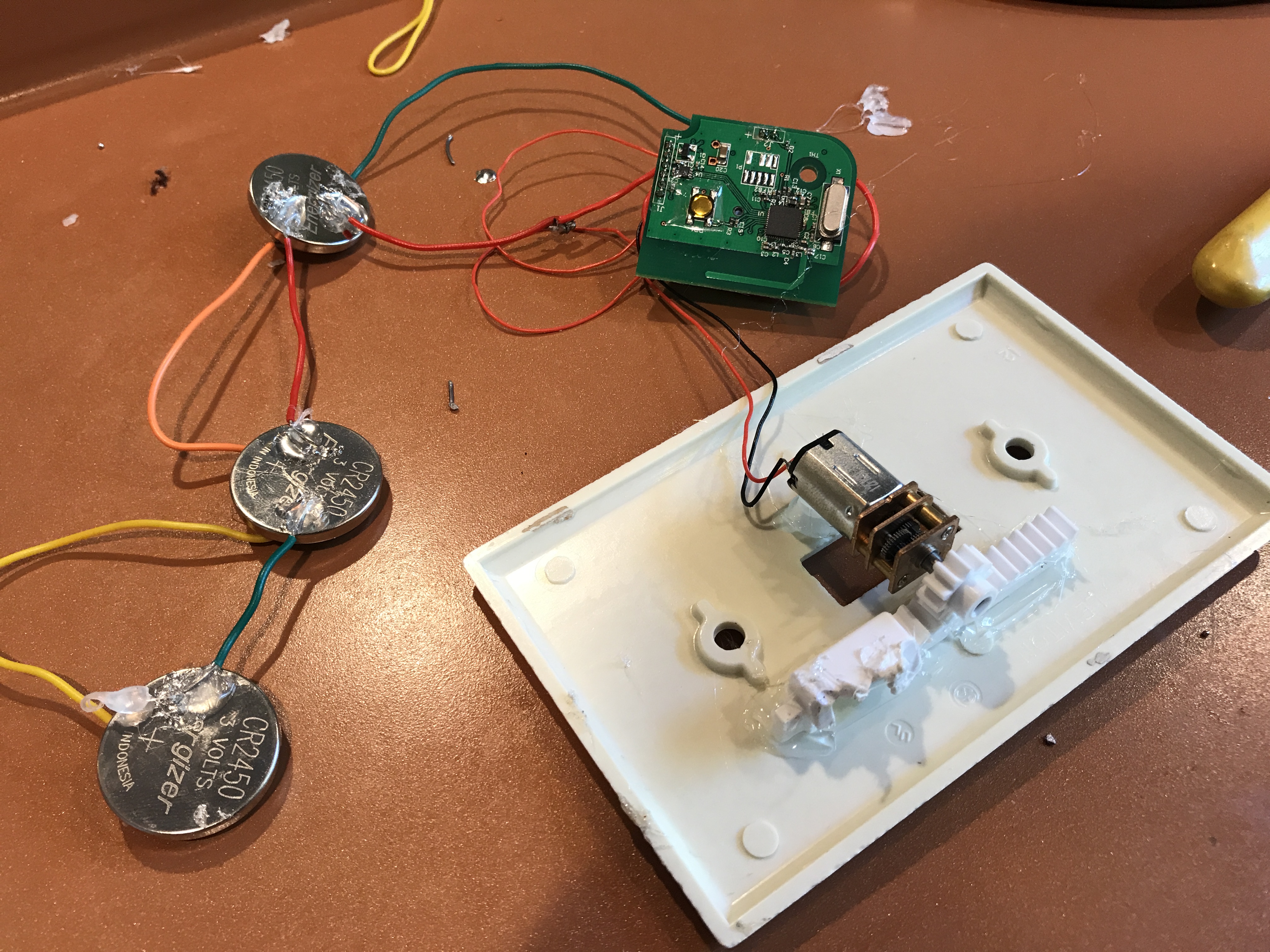

The raspberry pi would only be need to be connected to power and could be either connected to the network through a wireless connection, or through an ethernet port. As I began deciding which connection time would be more appropriate, I took a step back and reorganized my thoughts and end goal. I wanted to engineer an accessible and cost efficient device. After doing some calculations and more research into the parts I was using, I realized that the hub is the main reason why other products on the market are so expensive. I did some back tracking and realized using a hub would just not be logical for the goals I wanted to obtain. I began to research more ways of connecting these devices to the actual user. I began to notice how installing a bluetooth chip on the circuit board was a lot less expensive than using a wifi module, which ruled out using a wifi module. I then wanted to solely use bluetooth for the switch since it would cut down the price and eliminate the need for a hub. Hypothetically, I would have to use a button on the circuit board to rotate the motor in different directions until a more suitable design was set in place. It would be able to talk to the device directly through the network. Of course the problem with this was that if you are at work or away you wouldn’t be able to remote into the switch. I thought that the trade off would be worth it.

The raspberry pi would only be need to be connected to power and could be either connected to the network through a wireless connection, or through an ethernet port. As I began deciding which connection time would be more appropriate, I took a step back and reorganized my thoughts and end goal. I wanted to engineer an accessible and cost efficient device. After doing some calculations and more research into the parts I was using, I realized that the hub is the main reason why other products on the market are so expensive. I did some back tracking and realized using a hub would just not be logical for the goals I wanted to obtain. I began to research more ways of connecting these devices to the actual user. I began to notice how installing a bluetooth chip on the circuit board was a lot less expensive than using a wifi module, which ruled out using a wifi module. I then wanted to solely use bluetooth for the switch since it would cut down the price and eliminate the need for a hub. Hypothetically, I would have to use a button on the circuit board to rotate the motor in different directions until a more suitable design was set in place. It would be able to talk to the device directly through the network. Of course the problem with this was that if you are at work or away you wouldn’t be able to remote into the switch. I thought that the trade off would be worth it.

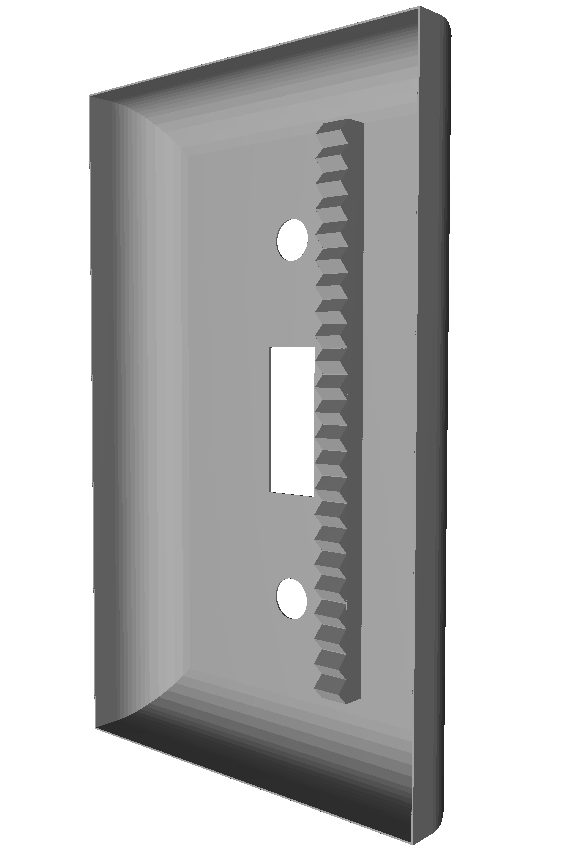

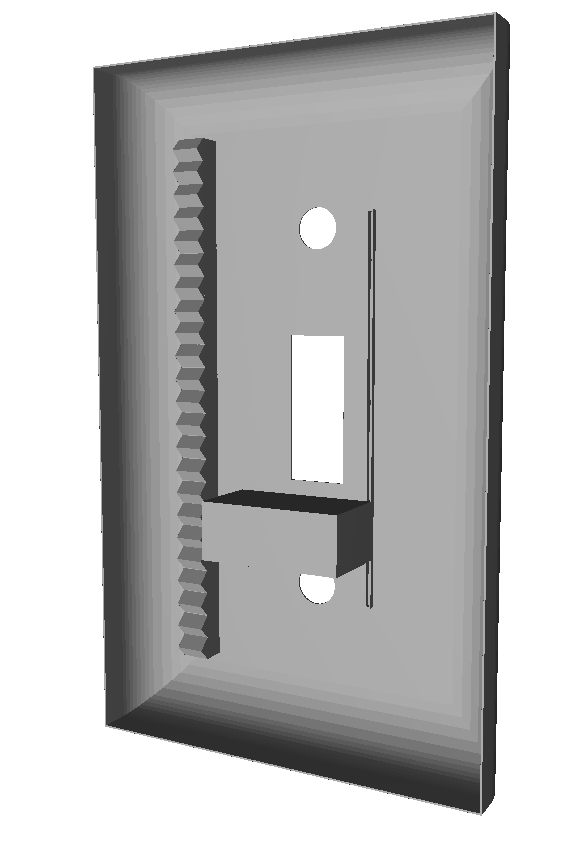

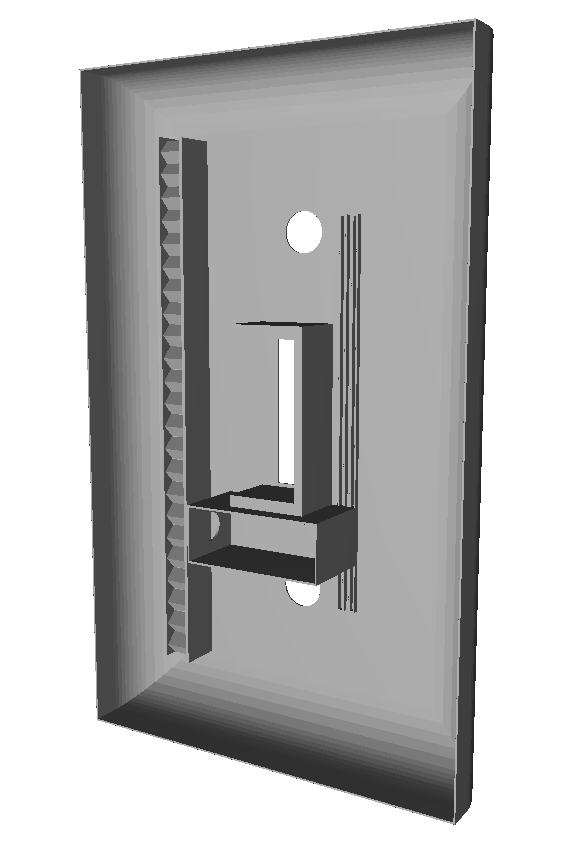

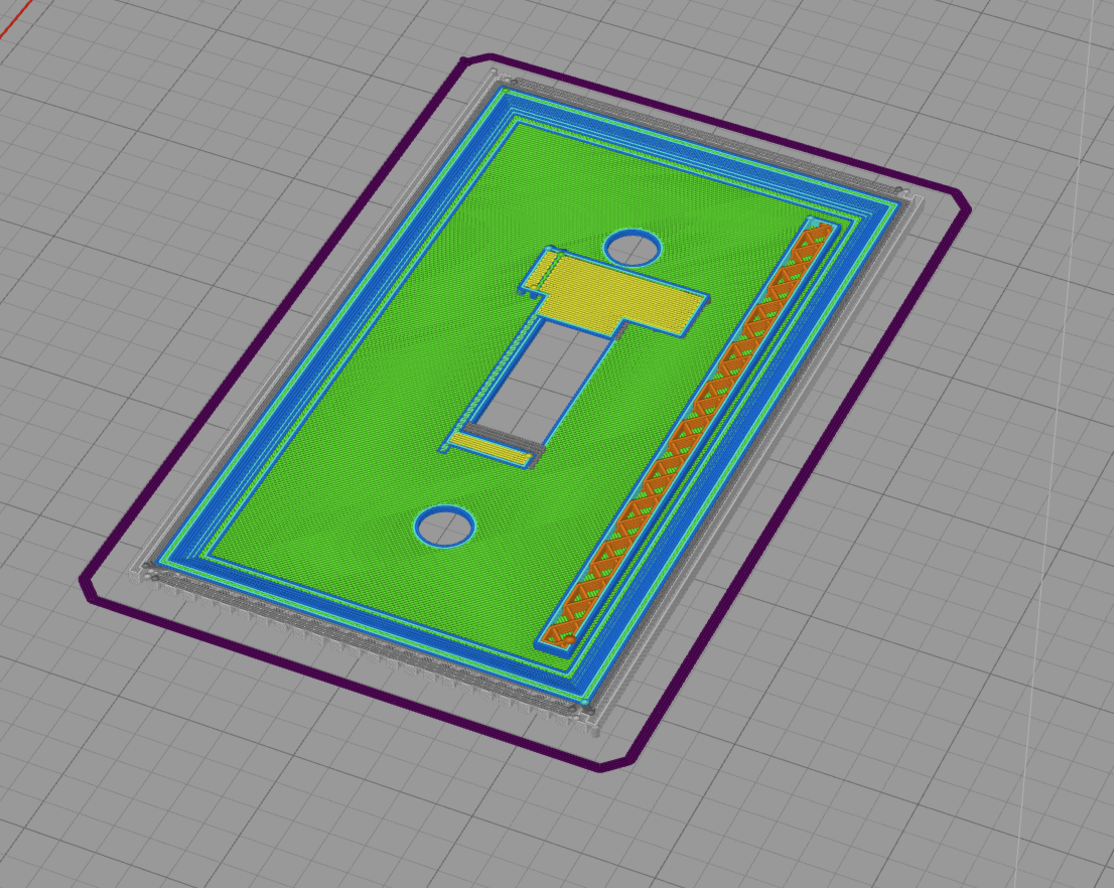

The only task the user would have is to unscrew the small frame on their light switch now and install this one. The batteries would require a removable compartment on the bottom that is not easily noticeable but still easy to access. The next step I took was to figure how how everything would fit and come together. Using Solidworks, I began developing tons of CAD designs to see how everything would look. I did run into the problem of the frame becoming very thick and nobody would want a thick piece of plastic hanging out of the wall.

The only task the user would have is to unscrew the small frame on their light switch now and install this one. The batteries would require a removable compartment on the bottom that is not easily noticeable but still easy to access. The next step I took was to figure how how everything would fit and come together. Using Solidworks, I began developing tons of CAD designs to see how everything would look. I did run into the problem of the frame becoming very thick and nobody would want a thick piece of plastic hanging out of the wall.

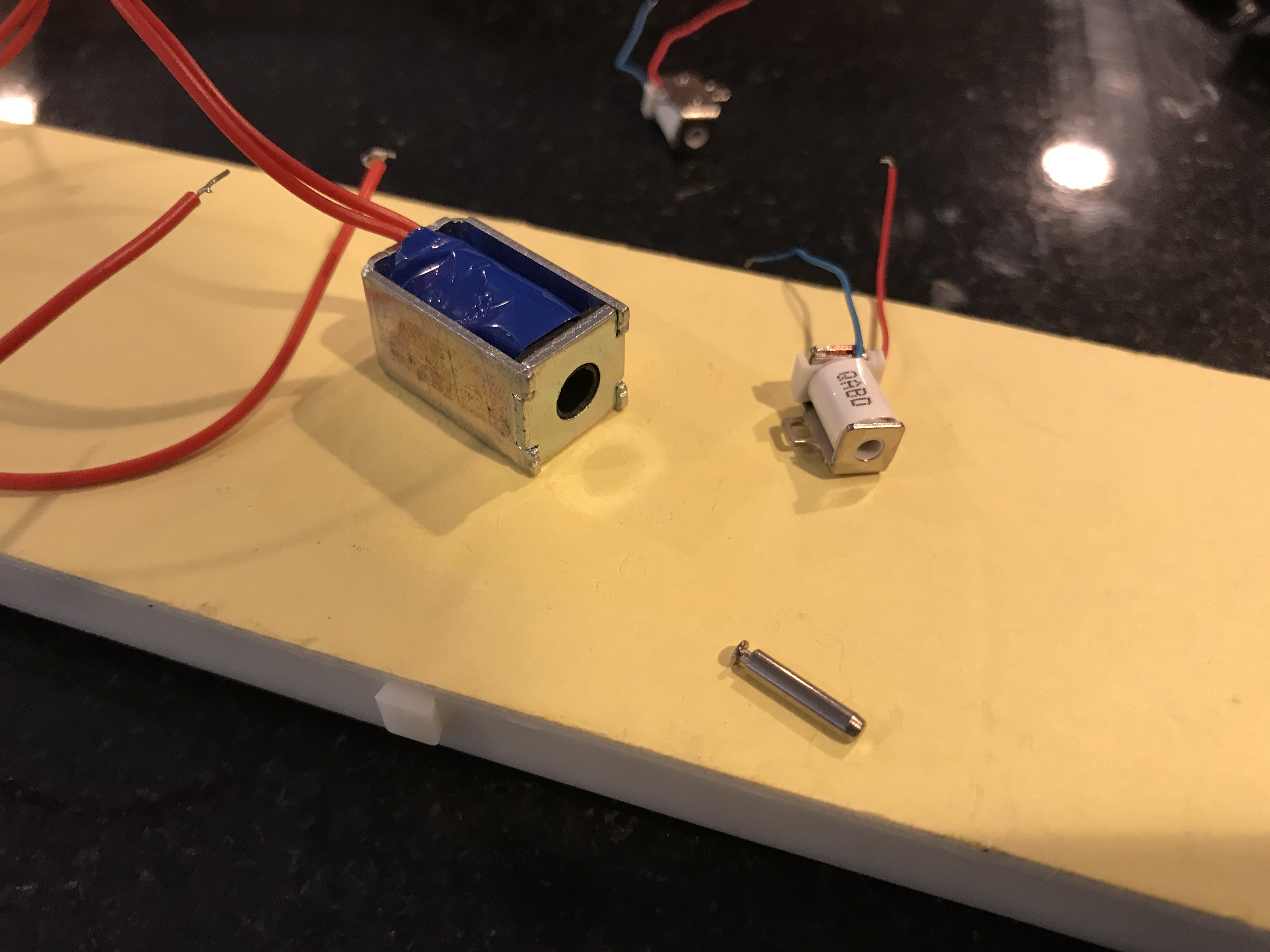

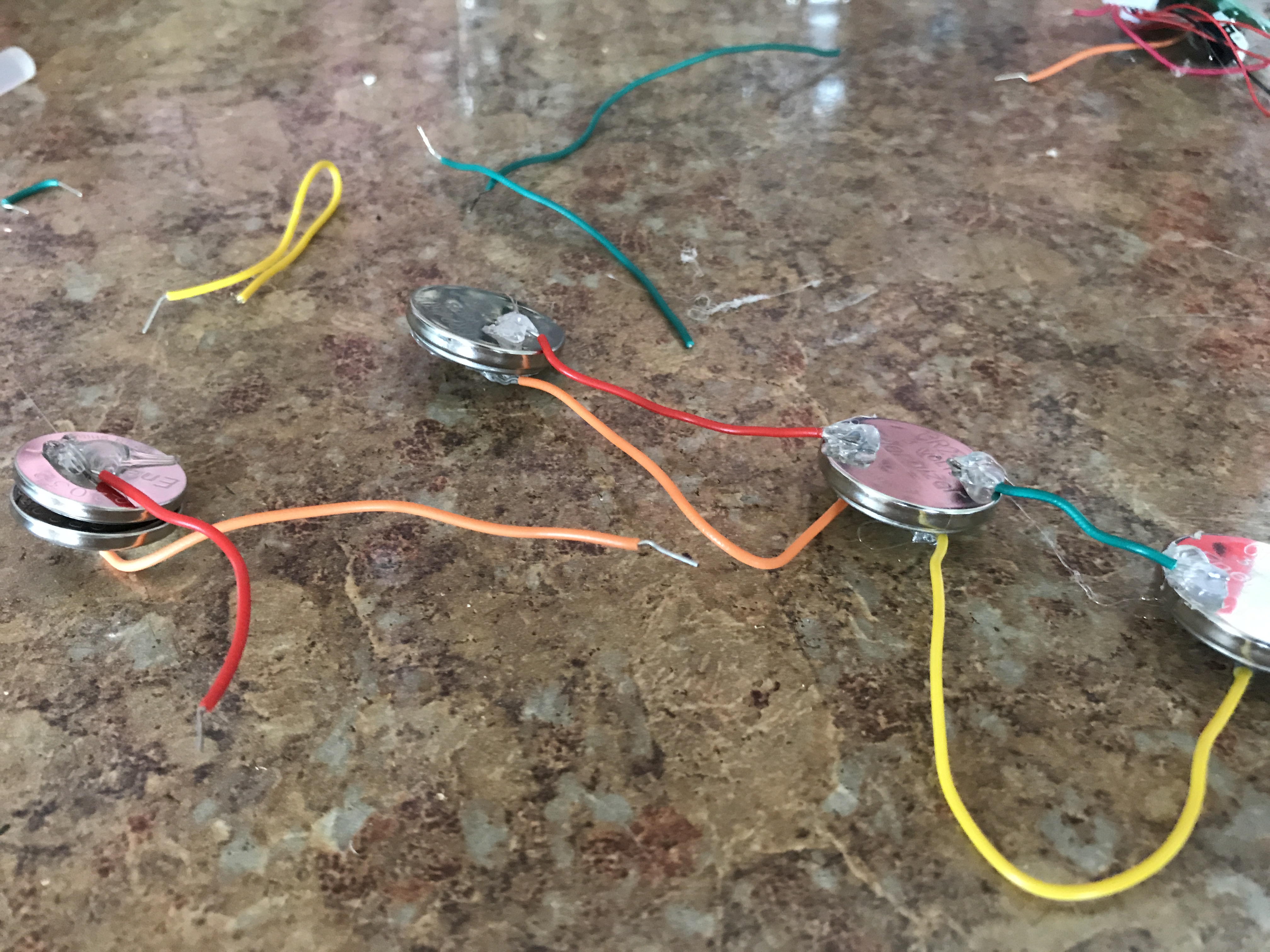

After going through more designs and testing, I was able to creating a mechanism that has the motor hooked up onto tracks with teeth at the end of the motor but also on a track. It would be able to move up and down by power produced by small CR2032 batteries in a small compartment. The motor would then lie in a small container that has a figure eight design to hold the motor but also outline the switch itself to pull and push on it.

I was able to push the depth of the frame down by having multiple tracks had the motor in a horizontal view and using coin batteries to power the device.

Utilizes: Microcontrollers, Android Development, Solid Works (CAD), Circuit Design, Serial Protocol, Linear Servo

After going through more designs and testing, I was able to creating a mechanism that has the motor hooked up onto tracks with teeth at the end of the motor but also on a track. It would be able to move up and down by power produced by small CR2032 batteries in a small compartment. The motor would then lie in a small container that has a figure eight design to hold the motor but also outline the switch itself to pull and push on it.

I was able to push the depth of the frame down by having multiple tracks had the motor in a horizontal view and using coin batteries to power the device.

Utilizes: Microcontrollers, Android Development, Solid Works (CAD), Circuit Design, Serial Protocol, Linear Servo